Troelli

Spinning

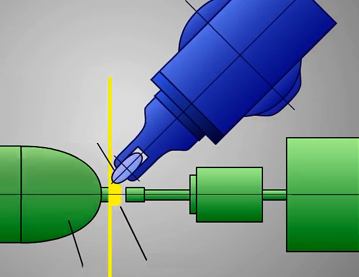

Troelli yw’r broses lle mae metel dalennog yn cael ei wthio dros ffurfydd crwn sy’n cael ei gylchdroi gan declyn. Mae’r metel wedyn yn cymryd union siâp y ffurfydd.

Gellir defnyddio’r broses droelli i wneud ffurfiau crwn gwag.

Mae’r hen grefft o droelli, lle defnyddid offer llaw ar durn, wedi cael ei disodli i raddau helaeth gan beiriannau robot cyfrifiadurol awtomataidd.

Bydd angen defnyddio’r teclyn gwthio fwy nag unwaith er mwyn gwthio’r metel i’w siâp.

Bydd hyn yn dibynnu ar nifer o ffactorau, gan gynnwys:

- Crymedd y darn

- Hyblygrwydd y metel

- Trwch terfynol wal y darn

- Faint o rym y gellir ei ddefnyddio

Mae’r cymwysiadau masnachol yn cynnwys lampau metel, offer coginio, poteli nwy ac offerynnau cerddorol pres.

Mae Troelli’n addas ar gyfer ffurfio darnau nad yw’n hawdd eu gwasgu.

Awgrym: Llai o wastraff a chostau is na llawer o ddulliau ffurfio eraill.

| Manteision | Anfanteision |

|---|---|

| Wyneb â gorffeniad llyfn da. | Costau cychwynnol uchel ar gyfer cynhyrchu ar raddfa fawr. |

| Costau’r offer a’r gwaith cynhyrchu’n gymharol isel. | |

| Gellir awtomeiddio’r broses droelli’n rhwydd. | |

| Dull cynhyrchu effeithiol ar gyfer prototeipiau yn ogystal â rhediadau cynhyrchu mawr. | |

| Gellir cyflawni nifer o brosesau peiriannu ar ôl gosod y peiriannau un waith. |

Spinning is the process where sheet metal is forced onto a round rotating former by a tool. The metal then takes up the exact shape of the former.

Spinning can be use to make hollow rounded forms.

Spinning using hand tools on a lathe has been largely replaced by automated CNC machines.

Forming the shape will require many passes of the tool to force the metal to shape.

The number of passes will depend on:

- Curvature of the component

- Ductility of the metal

- Eventual wall thickness of the component

- The force which can be exerted

Commercial applications include metal lamp shades, cookware, gas cylinders and brass musical instruments.

Spinning is suited to forming parts that cannot easily be pressed.

Tip: Less waste and lower costs than many other forming methods.

| Advantages | Disadvantages |

|---|---|

| Good smooth surface finish. | High setup costs for large scale production. |

| Tooling and production costs are also comparatively low. | |

| Spinning is easily automated. | |

| An effective production method for prototypes as well as high production runs. | |

| Several machining operations can be performed in one set-up. |