Sodro

Soldering

Mae sodro yn uno dau ddarn o fetel (sef: copr, pres, arian neu darnau bach o ddur) gan ddefnyddio gwres.

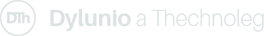

Dyma'r camau pwysig yn ymwneud a sodro arian:

- Anelio a glanhau y metel cyn sodro. Mae glanhau yn bwysig iawn oherwydd gall unrhyw faw neu saim ar yr uniad effeithio ar y broses.

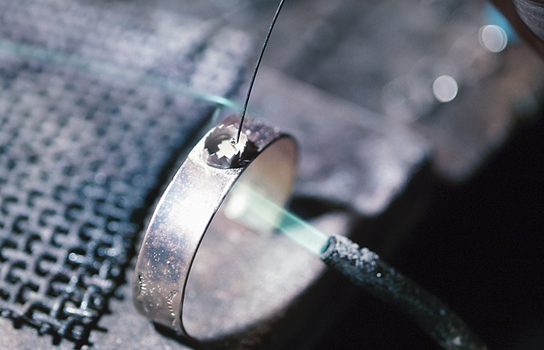

- Ychwanegu fflycs (Borax fel arfer) i'r uniad. Dylai'r uniad fod wedi ei pharatoi i ffitio heb fylchau. Defnyddir gwifren i rwymo darnau lletchwith neu darnau mawr gyda'u gilydd.

- Gosod tameidiau bychain o sodor ar hyd yr uniad cyn gwresogi.

- Cyfeirio gwres y fflam i'r darnau metel, ac nid at y sodor (bydd y sodor yn toddi drwy ddargludedd.

- Bydd y sodor yn rhedeg ar hyd yr uniad - ar y cam yma, tynnu'r gwres i ffwrdd a gadael i'r uniad oeri.

- Gellir glanhau'r eitemau mewn picl diogelwch.

Awgrym: Defnyddir sodor o wahanol raddau (gyda pwyntiau toddi gwahanol) er mwyn sodro cydrannau gwahanol o fewn un darn o waith.

| Manteision | Anfanteision |

|---|---|

| Mae uniad perffaith yn bosib sydd yn anweladwy wedi'i lanhau | Rhai eitemau yn cymeryd amser i'w cynhyrchu |

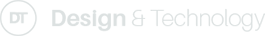

| Gellir uno darnau bychan iawn e.e. gwifrau a darnau man o emwaith. | Sgiliau uchel yn angenrheidiol. |

| Dim angen offer arbennigol. |

Soldering joins together two pieces of metal (usually copper, brass, silver or small pieces of steel) by using heat.

These are the important stages involved when silver soldering:

- Anneal and clean the metal before soldering. Cleaning is very important as any amount of dirt or grease on the joint will affect the process.

- Add flux (usually Borax) to the joint which must be a good fitting with no gaps– this will keep the joint clean (and free of oxidation) and help the solder to flow when it reaches its temperature. Binding wire is used for keeping awkward or large pieces together.

- A small piece of solder can be applied to the joint before heating.

- Point the heat at the pieces to be joined and not the solder itself (which will heat through conductivity).

- The solder will run along the join – at this stage remove the heat and let the item cool down.

- The items may be cleaned in safety pickle and washed.

Tip: Different grades of solder (with different melting points) are used when different areas within a piece need to be joined together.

| Advantages | Disadvantages |

|---|---|

| A very good join is possible which is invisible if cleaned well. | Time consuming in producing some items. |

| Very fine work may be joined i.e. wire or small pieces of jewellery. | High skill level required. |

| No specialist equipment required. |